Medical Breathing Air Dryers

- Guaranteed dew point performance

- Design simplicity

- No refrigerants used

- Purge saving & Dew point dependent control system

- Compact digital CO & Dewpoint Monitor/Alarm

- Air quality mandated by NFPA 99

- Bacterial Penetration up to 0.001%

- LED tower operation display indicating the sequence of

operation

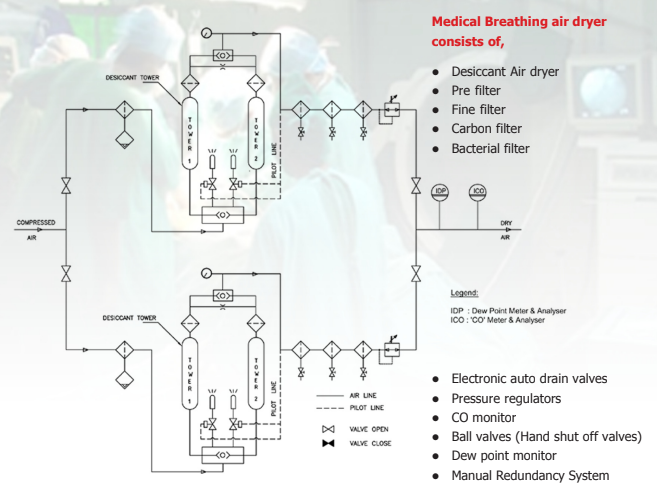

TBAS Medical Dryers

The TBAS medical dryers operate with the principle of Pressure Swing Adsorption, hence removing more moisture than refrigeration air dryers, and delivers moisture free dry air consistently irrespective of flow variation.

Description Of Operation

Drying cycle

The compressed wet air flows through the pre-filter. The Liquid water particles get filtered by the filter. The filtered air flows into the adsorber tower filled with desiccant where it loses all the moisture to the desiccant. Purified (Moisture and oil-free) air further passes through the series filter to achieve the desired quality level as per Breathing Standard.

Regeneration Cycle

In order to remove the moisture during regeneration cycle. Small portion of dry air from the drying tower is passes over the desiccant through the regeneration orifice. This results in complete regeneration of desiccant and ready for the next cycle.

TBAS medical breathing air dryer provides complete control of the system with LED indication/description of each step in the sequence of operation. A high-quality Carbon

Monoxide (CO) Monitor and Dew point monitor ensures the continuous monitoring of CO in PPM level and Water vapor concentrations in dewpoint deg oC in the Digital

display to ensure the safety of all users.

Bacterial filters (0.01 Micron) provide effective protection against various types of particles including bacteria, viruses, and moisture droplets in the dry air out from the medical dryer.

These are help to protect the patient, and the breathing circuit, hospital pipe line from contamination, odor and taste free dry air at the outlet.

This filter is used to remove oil and hydrocarbon vapor from the compressed air stream coming from the dryer. Odor and Taste free air at the outlet.

TBAS Outstanding features and applications

Alarms: Compact digital carbon monoxide (CO) monitor, Dew point monitor. If the set value exceeds the standard value, it will give the alarm in the front panel.

Purge saving: Manual Purge economizer. Dewpoint sensor for automatic purge control.

Construction: Corrosion-free aluminum towers and blocks. All pipelines are in SS/Copper.

Display: LED indication for tower operation and sequence of operations.

Easy Integration: Easy installation and integration with existing equipment: All system tie-in points are on one side.

Safe: Heavy-duty adsorption vessels, designed and certified for an unlimited number of cyclic loads.

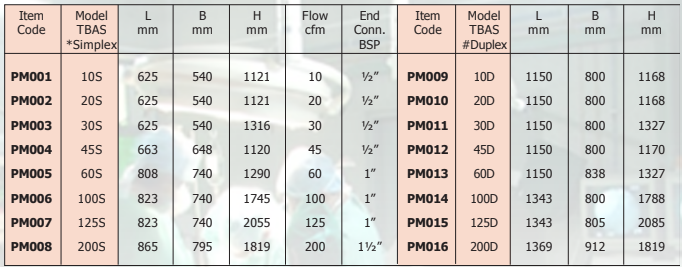

Customization: An extended list of options allow you to define your specific Trident Twin-Tower PSA breathing air dryer

adjusted to your individual need.