Oxygen Gas Generator

Oxygen Gas Generator

- System guidelines as per ISO 10083

- Oxygen Safe for medical use as per USP requirements

- Faster payback period

- Automatic switchover to the secondary oxygen supply

- Digital display – Oxygen purity & Pressure

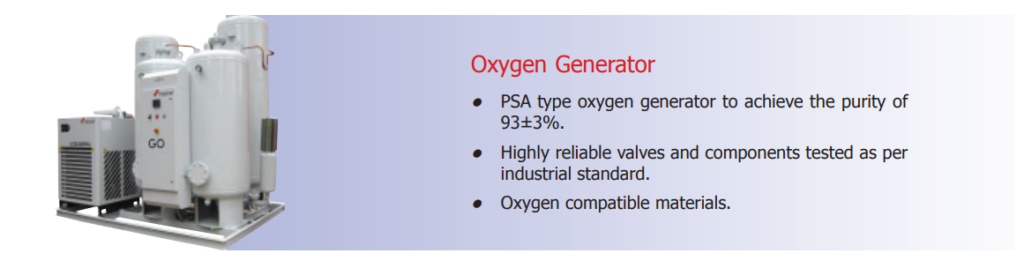

PSA BASED ON SITE OXYGEN GENERATION SYSTEM

The Trident on-site oxygen generator systems are perfect for anyone who wants their own flexible and reliable supply of oxygen without compromising on quality. Trident Oxygen Generators allow you to produce the gas exactly where you need it, when you need it

Benefits

- Produce as per Demand

- Avoid Cylinder Availability Issues

- Avoid Logistics and Management Problems

- Faster Payback period within 1Year and lesser

- Eliminate safety risks associated with handling high-pressure cylinders

- Can be used as a Mobile application also.

- Gas sensors and PLC Based Warning system

- Oxygen as per ISO 10083

- Concentration up to 93 ± 3%

Principle of Operation

- Drying Cycle: Purified (Moisture and oil-free) air from the compressed air system, Passing through one of the towers filled with Molecular Sieves (Zeolite type). The sieves selectively adsorb nitrogen, allowing oxygen to pass through at the desired purity level.

- Regeneration Cycle: During a regeneration cycle, the sudden depressurization brings out nitrogen molecules strapped in the sieve’s pores to the surface of the beads. A small portion of oxygen from the drying tower is passed over the sieves through the regeneration orifice. This results in the complete regeneration of Molecular Sieves. The automatic cycling of the adsorption and desorption between the two beds enables the continuous production of oxygen.

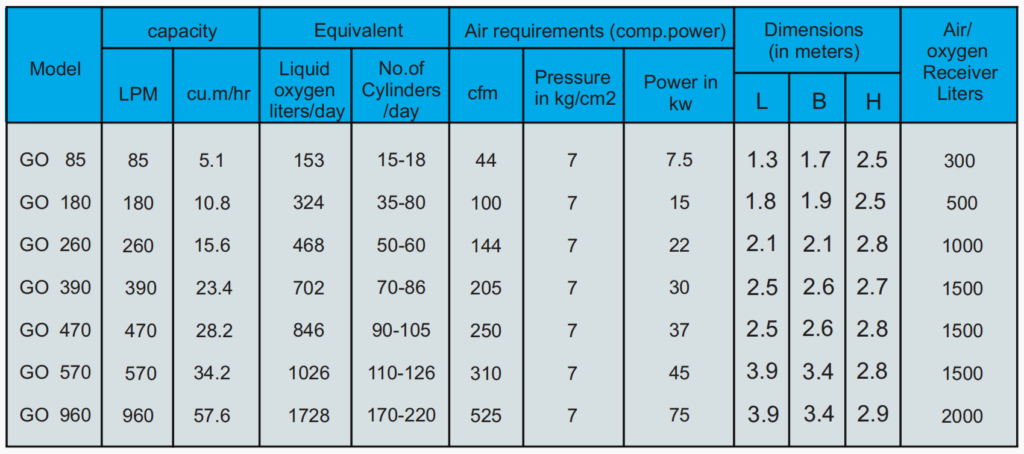

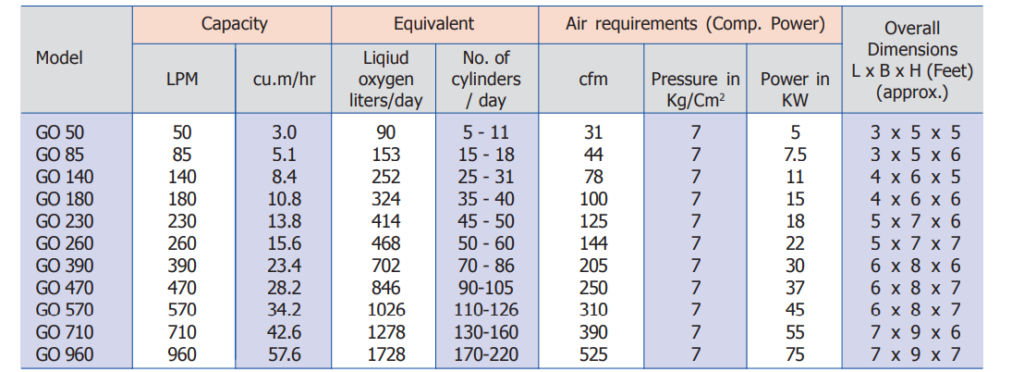

Specification

Oxygen Purity ………………………….. 93±3%

Oxygen Pressure ………………………. 4 – 5 bar a

Air pressure ……………………………. 7 bar g

Air Inlet Temperature ………………… 45 deg C max

Ambient Temperature ………………… 45 deg C max

Air quality ………………………………. ISO 8573 – 2010 class 1-4-1

Treatment Prodcuts included in the Scope